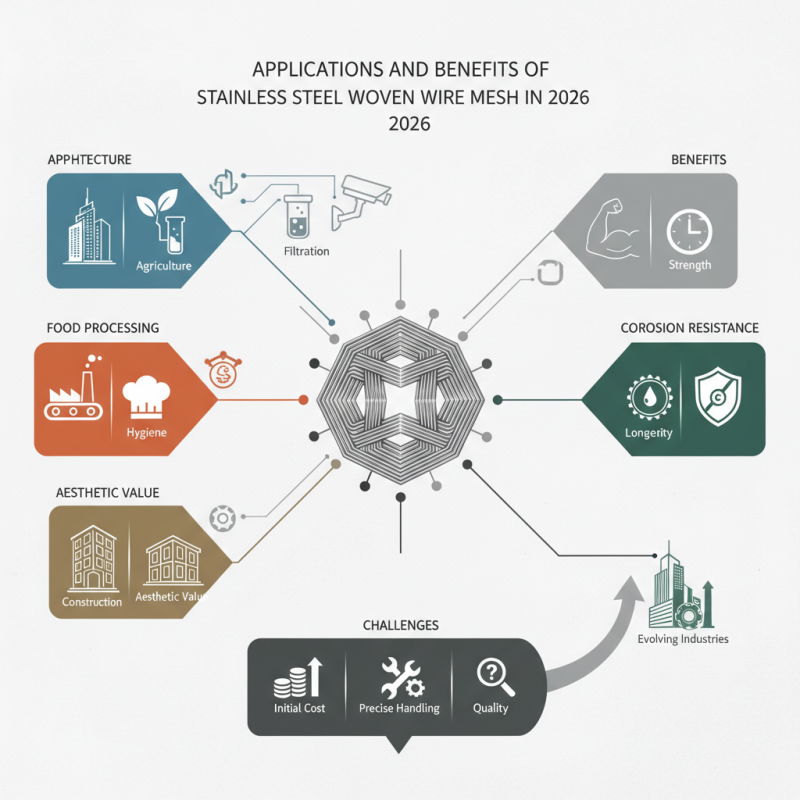

In 2026, the applications of stainless steel woven wire mesh are vast and varied. This versatile material plays a key role in many industries. From architecture to agriculture, it is widely used. Its durability and resistance to corrosion make it an ideal choice.

The benefits of using stainless steel woven wire mesh are numerous. It offers strength and longevity. Many businesses rely on it for filtration and security. For instance, food processing plants use it to ensure hygiene. In the construction sector, it adds aesthetic value.

Despite its advantages, challenges exist. The initial cost can be high, leading some to question its value. It requires precise handling during installation. Moreover, not all stainless steel woven wire mesh is created equal. Understanding quality is important. As industries evolve, so must the applications of this material.

Stainless steel woven wire mesh has become essential in 2026. Its technology has evolved significantly over recent years. The weaving technique improves both strength and flexibility. This mesh is now widely used across various industries, including food processing, filtration, and construction.

In the food industry, stainless steel woven wire mesh offers excellent protection against contaminants. It’s durable and easy to clean. This is crucial for maintaining hygiene and safety standards. Tips: Regularly inspect the mesh for wear and tear. Replacement is key for safety.

In construction, this mesh provides structural support. It’s lightweight but can withstand heavy loads. However, it’s not perfect. Over time, mesh can degrade, especially in harsh environments. Tips: Consider the environment when selecting the mesh type. Make adjustments as needed to ensure longevity.

This advanced technology provides numerous benefits. Yet, it is essential to acknowledge the limits of stainless steel woven wire mesh. Reflect on the requirements of your specific application to maximize the advantages it offers.

This chart illustrates the various applications of stainless steel woven wire mesh in 2026, with corresponding percentages representing their market usage. Food processing and filtration lead in applications, showcasing the material's versatility and essential role in multiple industries.

Stainless steel woven wire mesh serves various industries, offering unique advantages. This versatile material is used in filtration, safety, and architectural projects. Its corrosion resistance and durability make it ideal for harsh environments.

In the food and beverage industry, this mesh helps maintain hygiene. It can filter liquids without contamination. Many factories use woven wire mesh in sieves and strainers. However, the mesh must be cleaned regularly to prevent buildup.

In the construction sector, stainless steel woven wire mesh is essential for safety and support. It reinforces concrete and improves structural integrity. Yet, improper installation can lead to structural issues. Always ensure proper techniques are followed.

**Tips:** Choose the right mesh size for your application. A finer mesh will capture smaller particles, while a coarser one allows for faster flow. Regular maintenance is key for longevity.

| Application Area | Industry | Benefits | Mesh Size (mm) |

|---|---|---|---|

| Filtration | Chemical | Corrosion resistance, durability | 0.5 - 1.0 |

| Architectural Elements | Construction | Aesthetic appeal, strength | 2.0 - 5.0 |

| Safety Screens | Manufacturing | Worker safety, visibility | 1.0 - 3.0 |

| Cages and Structures | Agriculture | Durability, resilience | 3.0 - 6.0 |

| Sifting and Grading | Food Processing | Hygienic, efficient handling | 0.3 - 2.0 |

Stainless steel woven wire mesh offers numerous advantages in construction. This durable material provides excellent resilience against corrosion and weathering. It is ideal for use in various applications, such as facades and fencing. The fine openings in the mesh can add to aesthetic designs while ensuring structural integrity.

Using stainless steel woven wire mesh is cost-effective in the long run. Although initial costs may be higher than other materials, its longevity saves money on replacements. The mesh is lightweight yet sturdy, which facilitates easy handling during installation. However, some workers may find it challenging to cut or shape without the right tools.

Maintenance is relatively low compared to other materials. It requires occasional cleaning, but it does not rust easily. In areas of high humidity, users may need to be more vigilant. Overall, while stainless steel woven wire mesh may not be perfect, its benefits often outweigh its drawbacks in modern construction projects.

Stainless steel woven wire mesh is not just durable; it also offers significant environmental and health benefits. This material is highly resistant to corrosion and does not degrade over time, which means it can be recycled. Recycling reduces the need for new raw materials, helping to conserve resources. When used in construction or landscaping, stainless steel mesh helps to prevent soil erosion.

In terms of health, using stainless steel mesh minimizes contamination risks. Unlike plastics, it does not leach harmful chemicals into the environment. This is essential for food processing, where safety is paramount. Moreover, the cleanability of stainless steel ensures that surfaces remain hygienic. Spaces using this material may experience better air quality as well.

Despite these advantages, there are challenges. Processing stainless steel can require energy, impacting the environment. Additionally, its cost may limit accessibility for some applications. As industries strive towards sustainability, these are important aspects to consider. Balancing benefits with these concerns is crucial for future developments.

Stainless steel woven wire mesh is evolving rapidly. Innovations in materials and technologies are driving this growth. According to a recent industry report, the demand for woven wire mesh could reach $3.5 billion by 2026. This surge highlights the mesh's growing use in various sectors.

In the construction and filtration industries, woven wire mesh is seeing new applications. Enhanced corrosion resistance and versatility are key benefits. Various finishes improve performance in challenging environments. However, some users report durability issues under extreme conditions. Thus, further research is needed to address these concerns.

Future trends point towards smart applications. Many manufacturers explore integrating sensors with woven wire mesh. This technology can improve monitoring in industrial settings. Such advancements may increase efficiency dramatically. However, the costs associated with these innovations can be a barrier. Balancing innovation with affordability remains a critical challenge.

Utilizziamo i cookie per migliorare l'esperienza utente. Per maggiori informazioni, consulta la nostra Cookie Policy.