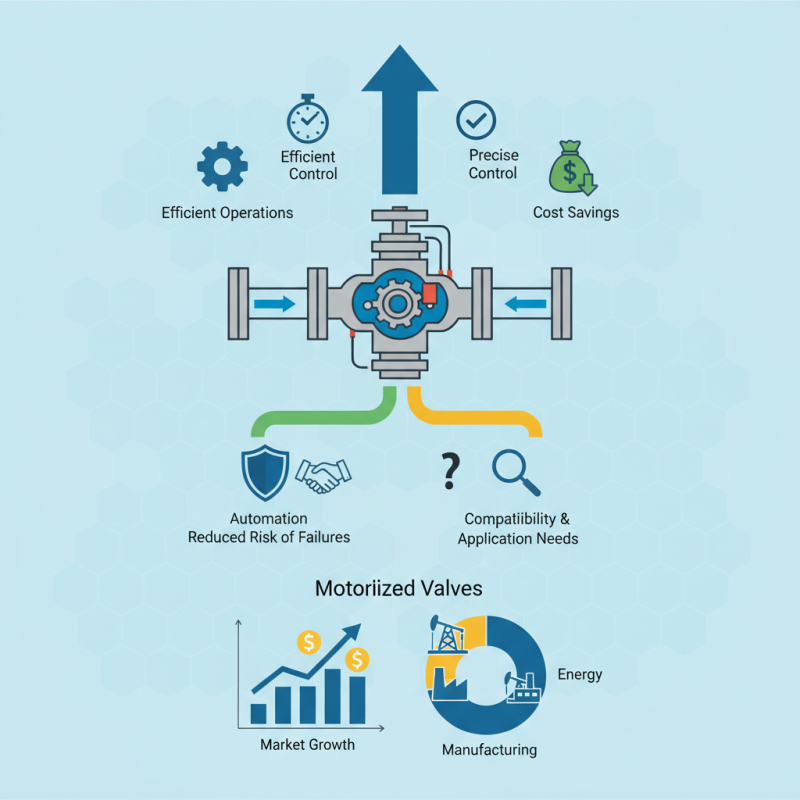

In today’s industrial landscape, the choice of components is critical. Motorized Valves play a vital role in ensuring efficient operations. According to a recent report by MarketsandMarkets, the global motorized valve market is expected to reach $3.21 billion by 2026, growing at a CAGR of 5.6%. This growth underscores their importance in various sectors, including manufacturing and energy.

These valves offer automation advantages that manual options lack. They provide precise control over fluid flow and pressure. This can significantly enhance operational efficiency. For example, in the oil and gas industry, a malfunctioning valve can lead to delays and increased costs. Motorized valves reduce the risk of such failures. Their consistent performance can result in savings on maintenance and downtime.

Still, selecting the right motorized valve is not always straightforward. Users must consider factors like compatibility and application needs. Not every system will benefit equally from a motorized valve. Some may experience unnecessary complexities. Therefore, careful evaluation is essential to maximize the benefits of these advanced components.

Motorized valves play a critical role in industrial applications. They provide precise control over fluid flow and pressure in various systems. These valves are operated using electric motors, allowing for automated operations. This automation enhances efficiency and reliability, reducing the need for manual intervention.

Understanding how motorized valves function is essential. They often include a valve body, actuator, and control mechanism. The actuator is responsible for opening or closing the valve based on electrical signals. This setup can be tweaked for different responses. Some installations may face challenges, such as miscommunication between the actuator and the control system.

Maintenance can also be tricky. Over time, wear and tear can affect performance. Regular inspections are necessary, but they are sometimes neglected. When issues arise, they can disrupt entire processes and lead to costly downtime. Recognizing these potential pitfalls can aid in improving operational strategies in the long run.

Motorized valves are gaining popularity in various industrial sectors. They offer precise control over fluid flow, which is crucial for efficient operations. According to a report by Grand View Research, the global motorized valve market size is expected to reach $11.58 billion by 2025. This growth highlights the increasing reliance on automation in industrial processes.

One of the key advantages of motorized valves is their ability to reduce manual intervention. This leads to improved safety and less risk of human error. Automation can enhance productivity and reduce operational costs. Industries that utilize these valves report a decrease in maintenance time, with many seeing up to a 30% reduction.

Tip: Regularly monitor the performance of motorized valves. Early detection of issues can prevent costly downtime.

However, it’s important to consider installation and compatibility with existing systems. Some facilities may face challenges integrating these valves. Conducting a thorough assessment before installation can save time and resources. Training for personnel on new equipment is essential for maximizing benefits and maintaining efficiency.

When evaluating motorized valves versus manual valves, several factors come into play. Motorized valves offer automation, which can greatly enhance efficiency. They allow for remote operation, reducing the need for manual intervention. This can be a significant advantage in hazardous environments. Manual valves require hands-on control, which can lead to delays. Workers need to be present to operate them, increasing risk in certain scenarios.

Reliability is another key aspect. Motorized valves maintain consistent performance. They can quickly respond to system changes. This reliability is crucial for processes that demand precision. On the other hand, manual valves may wear over time, leading to operational inconsistencies. They also require regular maintenance, which can be labor-intensive and time-consuming.

Cost is always a concern. Initial investments in motorized valves are generally higher. However, they can save money in the long run through reduced labor costs and efficient system management. Manual valves may appear cheaper initially, but their ongoing maintenance can add up. While both options have their merits, understanding specific needs is essential. Being aware of the potential drawbacks of each type can help in making a more informed decision.

| Feature | Motorized Valves | Manual Valves |

|---|---|---|

| Operation Type | Automatic operation with actuation | Manual operation by hand |

| Control Precision | High precision control | Variable control precision |

| Installation Complexity | Moderate; electrical setup required | Simple; no electrical setup needed |

| Response Time | Fast response to control signals | Slower due to manual operation |

| Maintenance Requirements | Lower frequency of manual checks | Higher frequency of checks and adjustments |

| Safety Features | Integrated safety options available | Safety relies on user operation |

| Applications | Suitable for automation in varied industries | Used in basic flow and isolation applications |

When selecting motorized valves for industrial applications, several factors should be considered. The type and size of the valve play crucial roles. Ensure the valve matches your pipeline specifications. Different industries might require varying materials. Stainless steel is often preferred for its corrosion resistance.

Think about the control method. Electric actuators are common due to their precision. However, pneumatic or hydraulic options can be suitable for specific applications. Each method has pros and cons. It’s important to reflect on your operational needs as this choice affects performance.

Tips: Assess your environment carefully. High temperatures or corrosive fluids can damage valves. Additionally, evaluate maintenance requirements. Some valves need regular servicing, while others are more user-friendly. Consider the frequency of use and ease of access for repairs. Balancing these factors will lead to better long-term performance.

Motorized valves are essential for various industrial applications. Their efficiency can greatly influence overall system performance. Regular maintenance is crucial for maximizing their benefits. While they provide convenience, improper care can lead to issues.

Routine checks on seals and actuators help prevent leaks and failures. It's important to schedule maintenance at set intervals. However, some industries neglect this, leading to costly downtime. Simple practices, like lubrication and inspection, can extend the lifespan of these valves.

In terms of energy efficiency, motorized valves optimize flow control. They reduce energy waste by ensuring systems operate within parameters. Unfortunately, many users overlook their settings. This oversight can result in increased energy consumption and operational inefficiencies. Attention to detail is key to harnessing the full potential of motorized valves.

Utilizziamo i cookie per migliorare l'esperienza utente. Per maggiori informazioni, consulta la nostra Cookie Policy.