Stainless Hexagon Bar has become a preferred choice for various engineering and manufacturing projects. In a recent report by the International Stainless Steel Forum (ISSF), the demand for stainless steel products is expected to rise by 5% annually. This growth underscores the importance of using quality materials such as Stainless Hexagon Bar.

Expert Mark Johnson, a well-respected figure in the stainless steel industry, states, “Choosing the right materials is crucial for longevity and performance.” His insight reflects the necessity for robust components in design and construction. Stainless Hexagon Bar offers exceptional resistance to corrosion, making it suitable for diverse applications ranging from automotive parts to structural supports.

However, issues such as availability and fluctuating prices can pose challenges. While the benefits are clear, understanding the market dynamics is essential. Careful consideration of these factors can result in smarter purchasing decisions. Ultimately, the choice of Stainless Hexagon Bar can enhance your project's durability and reliability.

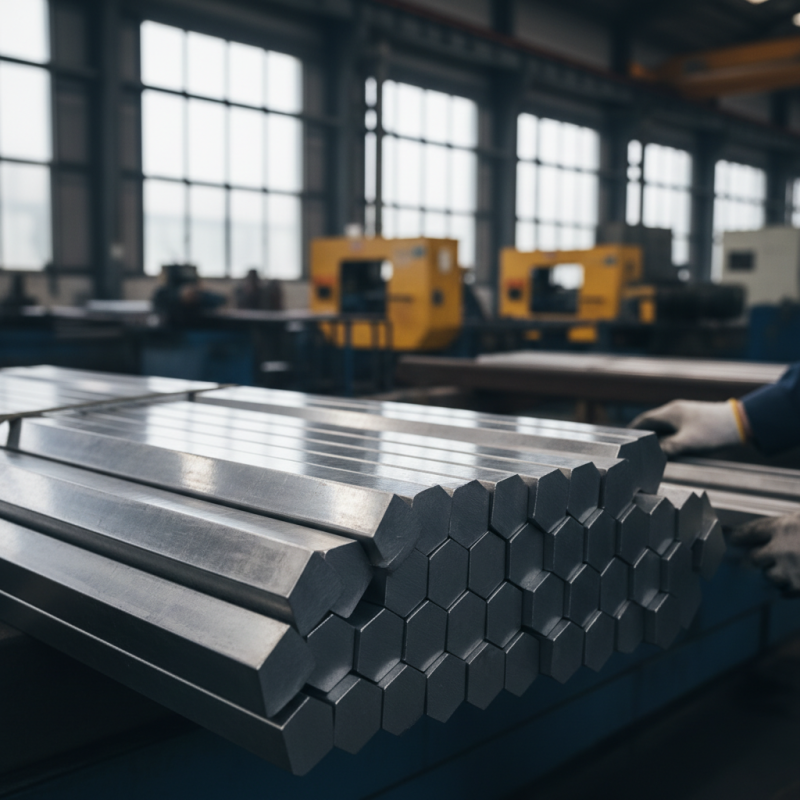

When considering metal options for projects, stainless hexagon bars stand out. Their unique shape allows for easy gripping and machining. These bars are ideal for applications that require strong resistance to corrosion. Industries like construction and manufacturing benefit significantly from this material.

Stainless hexagon bars are often used for fasteners and tools. Their durability ensures longevity in various environments. Additionally, the bars can withstand extreme temperatures. This flexibility makes them suitable for both indoor and outdoor use.

Tips: Always check for proper sizing before ordering. An incorrect measurement can lead to project delays. Consider the specific application to choose the right grade of stainless steel. Not all grades are equally effective for every job, and some might require special handling.

When it comes to bar manufacturing, various materials vie for attention. Steel, aluminum, and brass are common choices, but stainless hexagon bars stand out. Their corrosion resistance is a major advantage. A stainless bar does not rust easily, making it ideal for harsh environments. This quality ensures durability and long-term performance.

Comparing stainless hexagon bars to others, steel bars can rust quickly. They often require coatings to prevent degradation. Aluminum is light but lacks the strength of stainless steel. It may bend under pressure, which isn’t ideal for heavy load projects. Brass offers a distinct aesthetic, but it can tarnish over time. Each material has its purpose. However, stainless hexagon bars balance strength and resistance exceptionally well.

Choosing the right material is often a reflection of project needs. Sometimes, cost comes into play more than durability. This can lead to regret later. Investing in a material that withstands time may save money in the long run. Weigh these options carefully to avoid costly mistakes.

stainless steel hexagon bars are popular for many projects. They provide unique properties that significantly enhance results. The corrosion resistance of stainless steel is crucial. It keeps the material looking good and functioning well in various environments. Applications in outdoor settings often benefit from this durability.

Stainless hexagon bars find widespread use across various industries due to their strength and corrosion resistance. They are well-suited for construction applications. For example, many architectural projects utilize these bars for structural support. According to a report by the International Stainless Steel Forum, stainless steel accounts for over 60% of the material used in modern buildings.

In manufacturing, stainless hexagon bars serve crucial roles in producing fasteners and machine parts. Their precise dimensions make them ideal for use in CNC machining. ASTM standards emphasize the importance of using quality materials in these components to ensure safety and efficiency. However, industries sometimes overlook the necessity of quality grades, leading to issues like premature wear.

Moreover, the automotive sector increasingly relies on stainless hexagon bars. They are used in engine components and chassis frameworks, contributing to vehicle durability. A study from the Society of Automotive Engineers indicates a 15% increase in the use of stainless steel in vehicle production over the past five years. Yet, debates persist about whether manufacturers fully understand the lifecycle impacts of using different stainless steel grades. This uncertainty can introduce risk into sustainable practices.

When selecting a stainless hexagon bar, consider its strength and durability. Stainless steel is known for its resistance to corrosion. This makes it particularly appealing for outdoor and industrial applications. The hexagonal shape provides excellent grip and allows for easy clamping. This feature can be critical in many mechanical contexts.

Another crucial factor is the alloy composition. Different grades of stainless steel offer varying levels of hardness and flexibility. For instance, some might be more prone to scratching or denting. Think about the conditions your project will face. Will it experience high temperatures or exposure to chemicals? Evaluating these factors will help you select the right type, ensuring optimal performance.

Finally, don’t overlook the size and finish. The dimensions must match your project requirements closely. A rough finish may influence how well it works in certain contexts. Costs can vary widely based on these features. Sometimes, cutting corners on quality can lead to more significant issues down the line. It’s essential to weigh these considerations carefully before making a decision.

| Dimension (mm) | Weight (kg/m) | Common Applications | Corrosion Resistance | Advantages |

|---|---|---|---|---|

| 10 | 0.78 | Fasteners, Small Components | Excellent | Durable and Lightweight |

| 12 | 0.93 | Machinery Parts, Tooling | Very Good | High Strength and Rust Resistance |

| 16 | 1.56 | Framework, Automotive Parts | Excellent | Versatile and Long Lasting |

| 20 | 1.96 | Construction, Heavy Duty Applications | Outstanding | Cost-effective and more resilient |

| 25 | 2.43 | Industrial Equipment, Manufacturing | Excellent | Strong and Resilient to Weather |

Utilizziamo i cookie per migliorare l'esperienza utente. Per maggiori informazioni, consulta la nostra Cookie Policy.