Choosing the right stainless steel wire mesh can be overwhelming. With a variety of options available, understanding your needs is essential. Stainless steel wire mesh is not just a product; it serves many purposes. From filtration to safety barriers, each application requires specific features. The choice might seem straightforward, yet many get it wrong.

Consider the mesh size and wire diameter. Larger openings may meet some needs, but can compromise filtration. On the other hand, smaller openings provide better filtration but may restrict flow. The wrong choice can lead to inefficiency. Reflect on your requirements before making a decision.

Material quality is equally important. Not all stainless steel wire mesh is created equal. Different grades of stainless steel offer varying levels of corrosion resistance. If your environment is harsh, cheap options may fail — leading to costly repairs. It's crucial to balance cost with performance. A wrong choice can haunt you later.

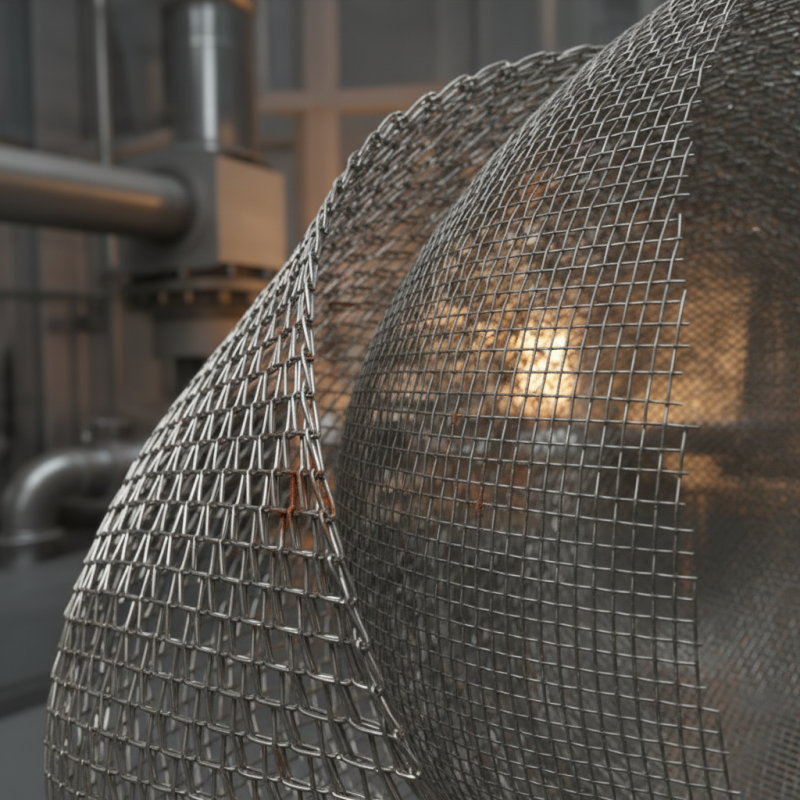

When choosing the right stainless steel wire mesh, understanding the available types is crucial. The primary types include welded wire mesh, woven wire mesh, and interlaced wire mesh. Each has its unique strength and application areas. Woven wire mesh, for example, is highly versatile due to its ability to create various mesh sizes. Often used in filtration, it can filter particles as small as 100 microns. Meanwhile, welded wire mesh is more suited for structural and security applications, owing to its robust nature.

Tips: Consider the mesh size and wire diameter when selecting. Balancing these factors can enhance performance for your specific needs. Remember that a tighter mesh offers finer filtration but may reduce flow rates.

Another important factor is the stainless steel grade. Common grades include 304 and 316, with 316 offering enhanced corrosion resistance. This is particularly useful in marine environments or chemical applications. However, 304 is more cost-effective and suitable for many general uses. Industry reports show the demand for these materials growing at a rate of 5% annually, underscoring their essential role in various sectors.

Tips: Assess your environment before making a choice. Corrosive conditions may necessitate a higher grade. Ignoring these factors can lead to premature failures.

When selecting stainless steel wire mesh, identifying your specific application requirements is crucial. Different industries demand unique specifications. For example, the pharmaceutical industry often requires high levels of sterilization, which involves meshes with finer openings. A report from the Stainless Steel Wire Mesh Association indicates that about 35% of wire mesh used in medical applications must meet stringent purity standards.

Consider the mesh's wire diameter. Thicker wires offer greater strength but can reduce flexibility. In contrast, finer wires can provide better filtration but may lack durability under tension. A recent survey found that 45% of industrial users prioritize strength for performance over filtration precision alone. Balancing these elements can be challenging.

Another factor to evaluate is corrosion resistance. Applications in marine or chemical environments require high-grade stainless steel types, as they offer greater longevity. Nearly 70% of users reported issues related to corrosion when inadequate materials were selected. It is essential to take time assessing your needs and materials. Understanding the environment and intended use can guide you to make a better choice.

When selecting stainless steel wire mesh, understanding specifications is essential. Different mesh types serve various purposes. Consider the mesh opening size. This affects airflow, light filtration, and strength. Smaller openings offer better filtration, while larger ones allow for increased visibility. Each application requires a unique mesh opening size.

Wire diameter is another crucial factor. Thicker wires enhance durability but may reduce flexibility. In contrast, thinner wires can be more pliable but may not withstand heavy loads. Balance is key here. Evaluate the overall construction of the mesh too. Welded options provide greater strength, while woven styles offer versatility.

Corrosion resistance is vital in demanding environments. Stainless steel has varying levels of resistance based on its alloy composition. This could be a blind spot if not researched thoroughly. Consider your specific environment when making a choice. If unsure, consulting with experts can provide clarity but may also reveal knowledge gaps. Take the time to think through these details to avoid costly mistakes.

Choosing the right stainless steel wire mesh involves understanding its corrosion resistance and strength. Different environments can greatly affect the performance of the mesh. For example, coastal areas with high salt exposure can accelerate rust. In these settings, selecting a mesh designed for high corrosion resistance is essential.

Strength is another crucial factor. Not all applications require the same strength level. Some projects need robust materials that can withstand heavy loads. Others may only require light-duty options. It's important to assess your specific needs before making a choice.

When weighing these characteristics, consider the mesh's grade. Some grades perform better than others in certain conditions. Certain grades can be stronger but less resistant to corrosion. This trade-off might not be immediately obvious. Testing different samples can help clarify which qualities you truly need. Reflecting on these aspects ensures a more suitable selection for your project.

Choosing the right stainless steel wire mesh involves careful consideration of both cost and availability. Industry reports show that prices can vary based on specifications, such as mesh size, wire diameter, and material grade. For instance, a finer mesh is often more expensive than a coarser one. Availability is also crucial; certain grades may be in high demand, leading to shortages and price fluctuations.

Cost is not just about the price tag. It includes shipping and potential delays. Research indicates that sourcing locally can reduce costs significantly. Local suppliers may offer better lead times compared to overseas options. We've seen quotes suggesting that buying domestically can lower total expenses by up to 20%. Be mindful that you may compromise on quality when chasing lower prices.

Tips: Always consult multiple suppliers for quotes. This helps gauge market prices effectively. Consider your project timeline; sometimes, waiting for a special order could save money. Lastly, don't hesitate to ask for samples. Assessing the material firsthand can prevent costly mistakes. When choosing, remember, reflecting on both cost and availability ensures you find the best fit for your project's needs.

| Wire Mesh Type | Mesh Size (Inches) | Wire Diameter (mm) | Cost per Square Foot ($) | Availability (Lead Time) |

|---|---|---|---|---|

| Standard Woven Wire | 1/4 | 0.6 | 5.00 | 1-2 weeks |

| Fine Mesh | 1/8 | 0.3 | 6.50 | 2-3 weeks |

| Heavy Duty Mesh | 1/2 | 1.2 | 8.00 | 3-4 weeks |

| Custom Mesh | Varies | Varies | Contact for Pricing | 4-6 weeks |

Utilizziamo i cookie per migliorare l'esperienza utente. Per maggiori informazioni, consulta la nostra Cookie Policy.