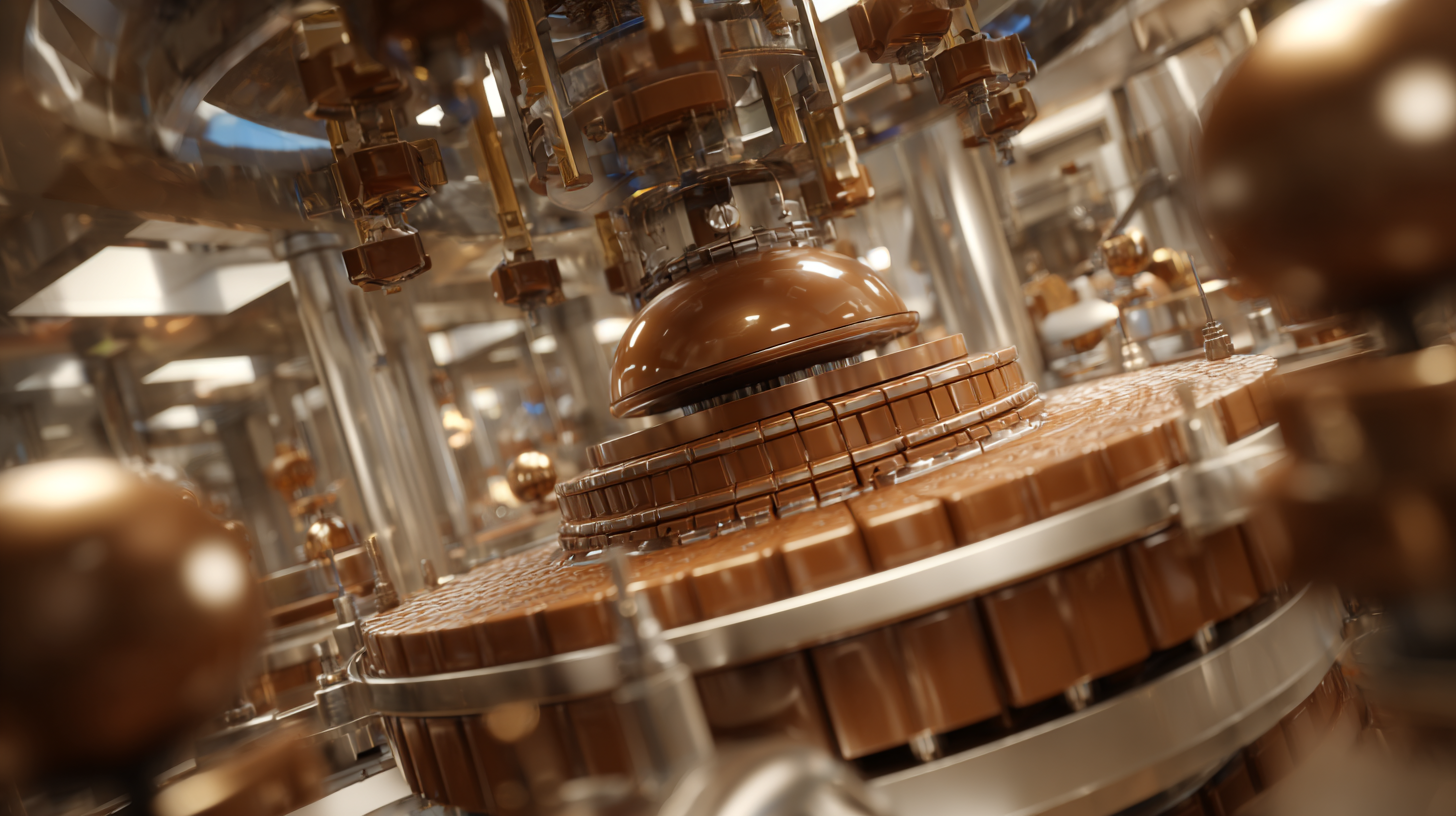

In the ever-evolving world of confectionery production, the demand for efficiency and quality is paramount, particularly in the chocolate industry, where the global market is projected to reach approximately $161.56 billion by 2024. As businesses seek innovative solutions to enhance their chocolate production, the exploration of alternative chocolate machines—known as "macchine per cioccolato"—becomes crucial. These cutting-edge technologies not only streamline operations but also improve the overall quality of the end product, allowing manufacturers to stay competitive in a saturated market. Reports suggest that implementing advanced machinery can boost production rates by up to 30%, while simultaneously reducing waste and operational costs. This guide aims to delve into the best innovative alternatives to traditional chocolate machines, highlighting their benefits and practical applications for modern chocolate production.

In the ever-evolving world of chocolate production, advanced technologies have revolutionized the way we create and process this beloved treat. Traditional chocolate machines, while effective, often come with limitations that can hinder efficiency and innovation. New alternatives, such as modular chocolate production systems and smart automation, are emerging as game-changers that not only enhance production capabilities but also improve product consistency and quality.

One significant advantage of these advanced technologies is their ability to integrate precision and control at every stage of the chocolate-making process. For instance, temperature-controlled mixing and refining techniques ensure that the chocolate maintains its desired flavor and texture, contributing to an exceptional final product. Furthermore, these innovative machines can facilitate real-time data analytics, allowing producers to monitor processes and adjust parameters for optimal results. By embracing these cutting-edge technologies, chocolate manufacturers are not only able to boost production efficiency but also stay ahead of market trends, catering to the growing demand for high-quality, artisanal chocolates.

When it comes to chocolate production, traditional machines have long been the backbone of the industry, offering reliable performance and time-tested techniques. These machines often feature familiar processes such as tempered heating and cooling systems, allowing manufacturers to achieve consistent quality and flavor. However, as the market demands faster production rates and greater customization, many producers are exploring innovative alternatives that promise to enhance efficiency and creativity.

Innovative chocolate machines, equipped with cutting-edge technology, provide exciting opportunities for production optimization. For instance, machines that utilize IoT connectivity can monitor and adjust parameters in real-time, ensuring that each batch is crafted to perfection. Additionally, some newer designs incorporate modular components that enable producers to easily switch between different recipes or techniques, offering unprecedented flexibility. By leveraging automation and data analytics, these innovative solutions not only streamline operations but also empower chocolatiers to push the boundaries of flavor combinations and product design. As chocolate makers weigh the pros and cons of traditional versus innovative machines, the choice ultimately hinges on the balance between reliability and the pursuit of creativity in their craft.

In the world of chocolate production, finding cost-effective solutions is paramount for manufacturers aiming to enhance efficiency without compromising quality. While traditional chocolate machines are revered for their reliability and performance, innovative alternatives have emerged that not only reduce operational costs but also offer unique production advantages. These alternatives leverage modern technology and inventive designs, enabling companies to produce high-quality chocolate with less energy consumption and lower material waste.

One notable alternative is the adoption of smaller, modular chocolate processing units. These machines offer flexibility in production capacity, allowing manufacturers to scale operations according to demand and reducing the need for expensive, large-scale machinery. Additionally, some newer machines incorporate automated features that streamline workflows, minimizing labor costs while maximizing output. By investing in such innovative solutions, chocolatiers can enhance their production capabilities while significantly lowering overhead expenses, ultimately leading to improved profit margins.

| Alternative Solution | Production Capacity (kg/h) | Initial Cost (USD) | Operating Cost (per kg) | Energy Efficiency (kWh/kg) | Maintenance Frequency (per year) |

|---|---|---|---|---|---|

| Batch Mixer | 100 | 25,000 | 0.50 | 0.2 | 2 |

| Continuous Conche | 200 | 45,000 | 0.40 | 0.15 | 3 |

| Chocolate Tempering Machine | 150 | 20,000 | 0.30 | 0.1 | 1 |

| 3D Chocolate Printer | 50 | 35,000 | 0.70 | 0.25 | 4 |

| Cocoa Bean Roaster | 120 | 15,000 | 0.45 | 0.18 | 2 |

In the competitive landscape of chocolate manufacturing, efficiency is paramount, and new machine technologies are rising to meet this challenge.

Advanced chocolate machines not only streamline production processes but also enhance product quality. According to a report by Grand View Research, the global chocolate market is expected to reach $161.56 billion by 2024, propelling manufacturers to seek innovative solutions to increase output while maintaining flavor integrity.

One notable development is the integration of automation and AI in chocolate production lines. These technologies allow for precise control of temperature and mixing times, leading to a more consistent product. A study by the International Journal of Food Science and Technology found that automation reduces production time by up to 30%, allowing manufacturers to boost their productivity without sacrificing quality. Furthermore, energy-efficient machines are gaining traction, reportedly cutting energy consumption by 20%, which is not only cost-effective but also environmentally sustainable.

Additionally, the emergence of 3D chocolate printing is revolutionizing how manufacturers approach customization and design. This technology offers unprecedented flexibility, enabling the production of complex shapes and structures that were previously difficult to achieve. As noted by Market Research Future, the 3D printing segment in food manufacturing is projected to witness a CAGR of over 20% through 2025, illustrating the potential for chocolate makers to leverage innovative machinery to meet evolving consumer demands.

In the quest for sustainability in chocolate production, innovative technologies are taking center stage. Recent collaborations in the industry, such as the venture aimed at cellular agriculture, are set to redefine cocoa sourcing without traditional farming practices, potentially reducing the environmental impact associated with conventional cocoa cultivation. This shift not only addresses ethical concerns but also aligns with the increasing consumer demand for products that prioritize sustainability.

Moreover, robotics and AI-driven technologies are transforming chocolate manufacturing, enhancing efficiency and reducing waste throughout the production process. These advancements allow manufacturers to optimize ingredient use and streamline operations, responding effectively to market challenges while maintaining high standards for quality. Innovative equipment, including agro-processing tools provided to community producers, is instrumental in empowering local farmers and promoting sustainable practices, ultimately leading to a more responsible chocolate supply chain.

Utilizziamo i cookie per migliorare l'esperienza utente. Per maggiori informazioni, consulta la nostra Cookie Policy.